Gerard Vilarrassa, Product Manager of Kivnon

Mobile robots such as automatrd guided vehicles and autonomous mobile robots are self-driving vehicles that carry loads from one industrial operation to another.

The first generation of mobile robots improved efficiency by automating picking, bringing parts to a conventional conveyor line, and moving finished goods from the end of the production line to the warehouse for eventual shipping.

Such automation improved productivity and ergonomics by eliminating the myriad step pickers or operators might have had to take otherwise.

However, as consumer began demanding more product variability and faster delivery, fixed conveyor systemas have inherent inefficiencies that make them less suitable for these emerging needs.

Their single-stream workflow of conveyor belts also enforces rigid assembly sequences. Even though they may work on only part of the car, appliance or whatever is on the line, line workers may have to sit idle while watching other product sections go by.

If there is a delay upstream, downstream workers may have to sit idle waiting for upstream operations to complete. All of which adds delays and costs to the operation.

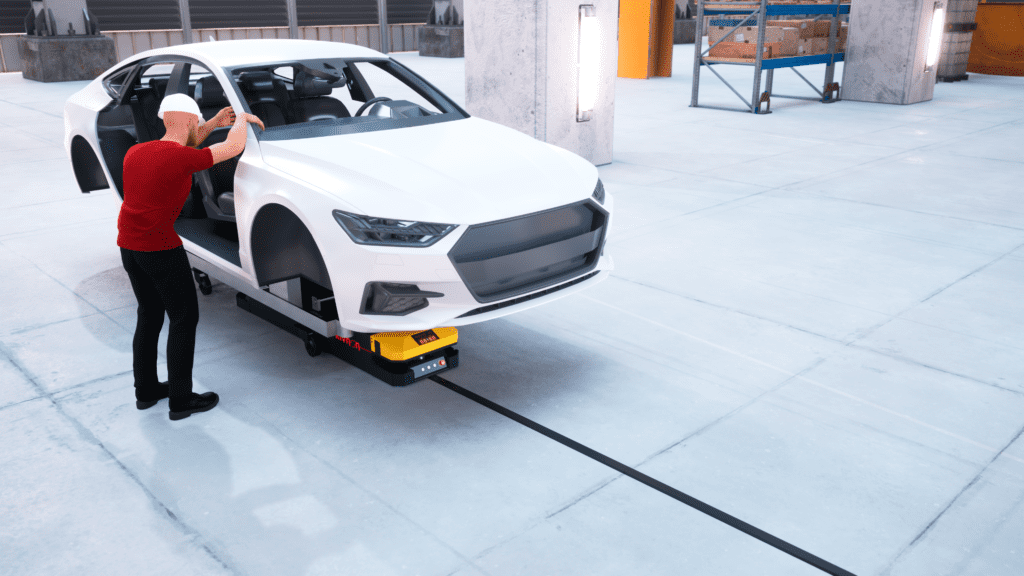

Rethinking the assembly line as a configuration of distributed but integrated mobile robots changea all that, raising manufacturing efficiency, flexibility, customizability, and profitability to new heights.

Manufacturing system designers may also equip mobile robots with tools, such as robot arms that involve them in conducting the operations.

Also improving efficiency is that robots can work 24/7, maximizing production flow. They can perform repetitive tasks, minimizing human error that can lead to defects or rework.

Given the improvement in effectiveness, flexibility and customization mobile robots represent a more secure investment than a conveyor belt-based system for at least the following reasons.

Gerard Vilarrasa is the Product Manager at Kivnon. Electrical engineer with almost a decade of experience in the industrial sector, the majority of them in mobile robotics product development and management at Kivnon.