Cooperative Automation: the new frontier

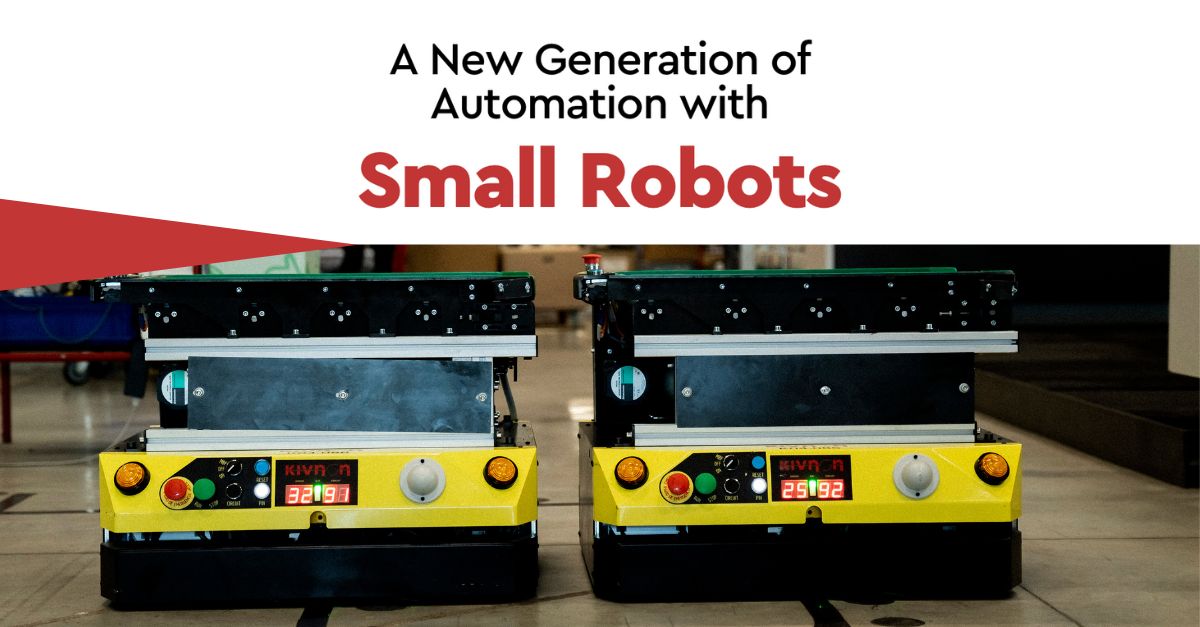

The integration of Autonomous Mobile Robots (AMRs), such as those developed by Kivnon, with innovative humanoid robots, like AEON from Hexagon, is driving the next phase of industrial automation.

This collaboration represents a shift toward collaborative, precise, and autonomous automation, capable of handling complex processes in a decentralized manner.

This synergy not only boosts operational continuity, but also redefines how industrial value chains are configured across sectors like automotive, aerospace, advanced manufacturing, and logistics.

- Component Inspection:

The humanoid robot autonomously scans industrial parts while the AMR executes intelligent transportation between stations, enabling fast and accurate inspection workflows.

- Digital Environment Capture:

While AEON generates digital twins using augmented reality sensors, Kivnon’s AMRs adapt to real-time layout changes, using advanced SLAM-based mapping for optimal navigation.

- Advanced Maintenance & Machine Tending

The humanoid robot operates physical controls or adjusts CNC machinery, while the AMR delivers tools or parts in continuous motion.

- Remote Industrial Teleoperation

Both robots can be operated remotely from control centers, offering full synchronization between mobility and manipulation—ideal for critical tasks in high-risk environments.

Key technical benefits

1. Continuous Autonomy

Both the humanoid robots and Kivnon AMRs use automated battery swapping systems, removing charging downtime and supporting uninterrupted multi-shift operations.

2. Precision & Advanced 3D Perception

AEON integrates multimodal sensors and spatial reasoning to understand dynamic industrial environments. Simultaneously, Kivnon’s AMRs ensure full layout traceability and high-precision SLAM-based navigation.

3. True Operational Flexibility

This collaboration enables automation of frequently changing tasks without mechanical reconfiguration, making it ideal for high-mix, low-volume environments.

4. Modular Scalability

Both humanoid and mobile robotic systems can be deployed in phased rollouts, scaling with the plant’s maturity and automation goals. This makes them viable in both greenfield and brownfield factories.

Real world industry pilots

Humanoid robotics from Hexagon are currently being tested by Schaeffler and Pilatus in scenarios such as automated inspection, environment digitization, and complex part handling.

In parallel, Kivnon offers a robust portfolio of Autonomous Mobile Robots (AMRs) that are ideal for integration in advanced industrial automation setups involving humanoid collaboration. These include:

- K05 Twister – Offers exceptional maneuverability for operations in tight and dynamic environments.

- K55 Pallet Mover – Automates heavy-duty pallet transport, streamlining intralogistics.

- K11 Two-Way – Enables bidirectional navigation, perfect for flexible routing in complex layouts.

These AMRs are designed to complement a variety of robotic systems, enabling modular deployment, real-time mobility, and scalable automation for smart factories across industries.

The integration of precision humanoid robots and autonomous mobile robots is no longer a futuristic vision—it’s a mature, deployable robotics architecture.

Factories that embrace this convergence will lead the Industry 4.0 transformation, gaining competitive advantages in traceability efficiency and response speed.

Want to explore how Kivnon AMRs can integrate with humanoid robots in your factory?