Collaborative Robots (Cobots) and AGVs are both automation technologies that when you mix it, you get the best of both worlds

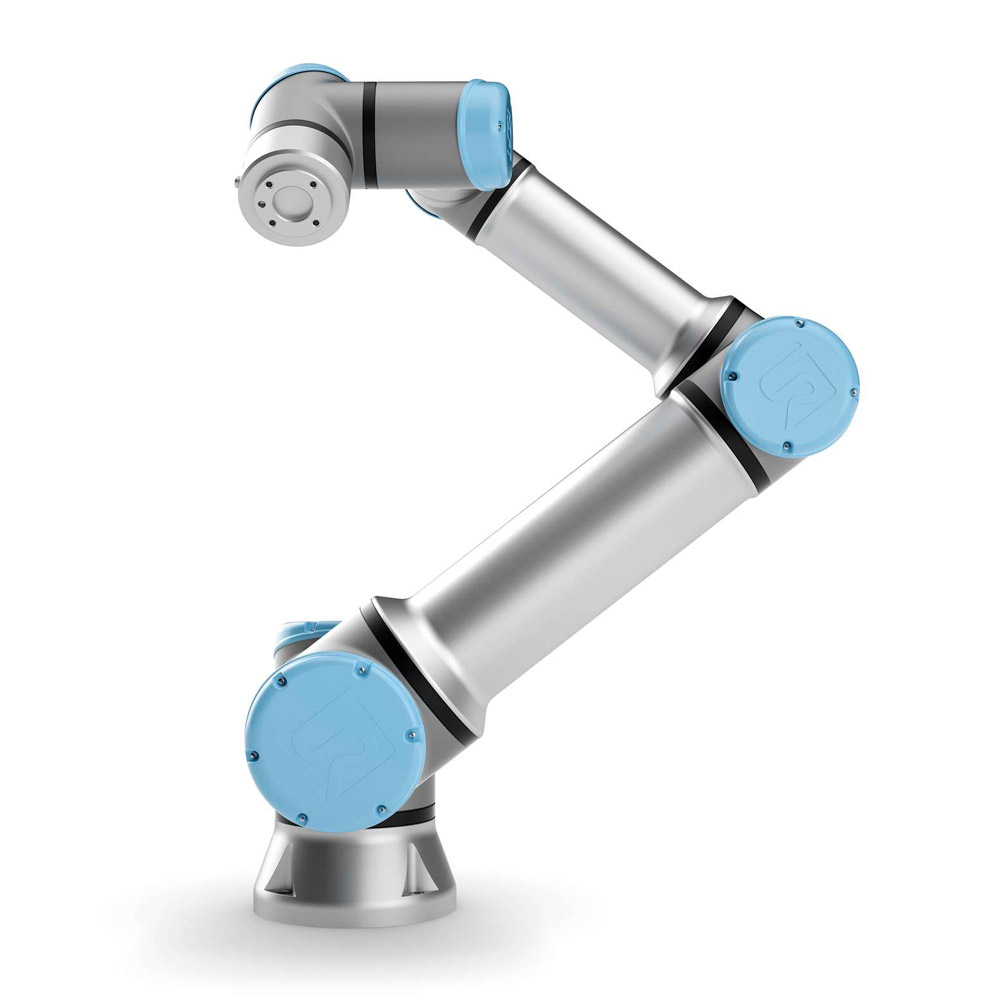

Collaborative robots, or Cobots, are designed to work alongside human operators in order to solve problems. Cobots are easy to program and feature safety sensors that prevent them from unexpectedly harming humans. This kind of automation technology can be used in a variety of industries and applications, from electronics manufacturing to food processing to woodworking, between others.

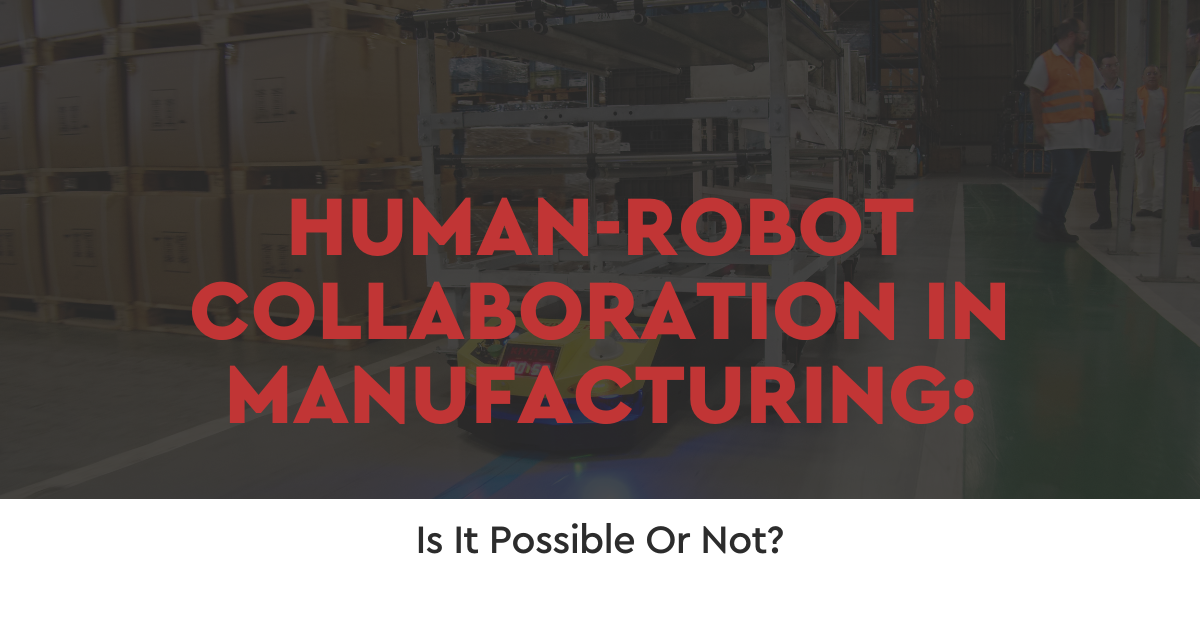

Automated Guided Vehicles (AGVs) are mobile robots that transport materials, products, and tools in industrial settings. AGVs are used to automate assembly lines, warehouses, and more. These robotic workers follow a predetermined path while avoiding obstacles and delivering products reliably to their destinations.

Both Cobots and AGVs can help increase efficiency, productivity and safety in industrial enviroments. Here are some examples of how they can be integrated:

- Material Handling: An AGV can transport materials to a workstation where a cobot performs the actual assembly or handling tasks.

- Order fulfillment: An AGV can bring parts and components to a cobot, which then assembles the final product. The completed product can then be transported by another AGV to a shipping or storage area.

- Palletizing: Cobots can be used to pick and place products onto pallets, which can then be transported by AGVs to a storage or shipping area

Integrating cobots and AGVs makes them more useful, adaptable and efficient. There are several reasons why integrating cobots and AGVs can be beneficial for companies such as:

- Increased Efficiency: Automate repetitive or hazardous tasks. You’ll have more time to do what matters the most to your business—deliver great customer service and build lasting relationships with partners.

- Reducing costs: As the job market continues to be competitive, labor expenses have increased and will continue to rise. Automation can reduce labor costs by replacing manual tasks with automated systems.

- Increased Safety: This kind of automation systems are designed to be safe for humans to work alongside. This means employees can continue to perform other tasks without the worry of injury.

- Scalability: Cobots and AGVs can be scaled up or down to meet your production needs. With increased flexibility, companies can respond quickly to fluctuations in demand.