Revolutionizing Industries: Kivnon mobile robots as the Catalyst for agile solutions

Over the last two decades, flexibility has been considered one of the most important determinants in production system design – especially in the wake of Industry 4.0.

Traditional production environments contain rigid production systems while static layouts and process routing hinder productivity. To transform the traditional production environment, processes born under the demands of Industry 4.0 need to promote virtualization, decentralization, and network building. This is where the use case for autonomous mobile robots (AMRs) comes into play.

Flexible robotic solutions for greater industry advancement

Intelligent autonomous material handling systems – in configuration with AMRs – affect the flexibility and productivity of process industries through intralogistics in production systems and cloud manufacturing.

Flexible navigation systems can support improvements in transportation, for example, an AMR is adopted to obtain feasible solutions for boosting the flexibility and efficiency of production systems. AMRs seamlessly transport materials and components to assembly lines, simply reducing manual labor and minimizing production delays.

By automating the movement of start-to-end products, logistics operations are streamlined and productivity is heightened. Moreover, it creates an adaptable and more robust supply chain capable of meeting fluctuating market demands.

The flexibility of these mobile robots needs to be robust and reliable enough to stretch across industries – especially since market demands could plummet or skyrocket at any given time. At Kivnon, we place immense importance on designing machinery that seamlessly adapts to its environment and simplifies the entire integration process – no matter the industry.

How Kivnon provides agile, industry-specific solutions

Our extensive network of over 50 clients around the world is a testament to our commitment to driving innovation and efficiency. Through a combination of agility and expertise, we’ve become a transformative force, collaborating with businesses across the board to revolutionize their internal processes.

Tailored robotic solutions meet the demands of each client and our fleet of innovative mobile robots carry out the hard work to create safer and more productive environments. Our experience includes (but is not limited to) the following industries:

- Automotive industry

Our robotic solutions play an essential role in streamlining production lines, optimizing material handling, and enhancing assembly processes within automotive manufacturing. Our robust and innovative fleets integrate into existing workflows, ensuring smoother operations and improved production throughput.

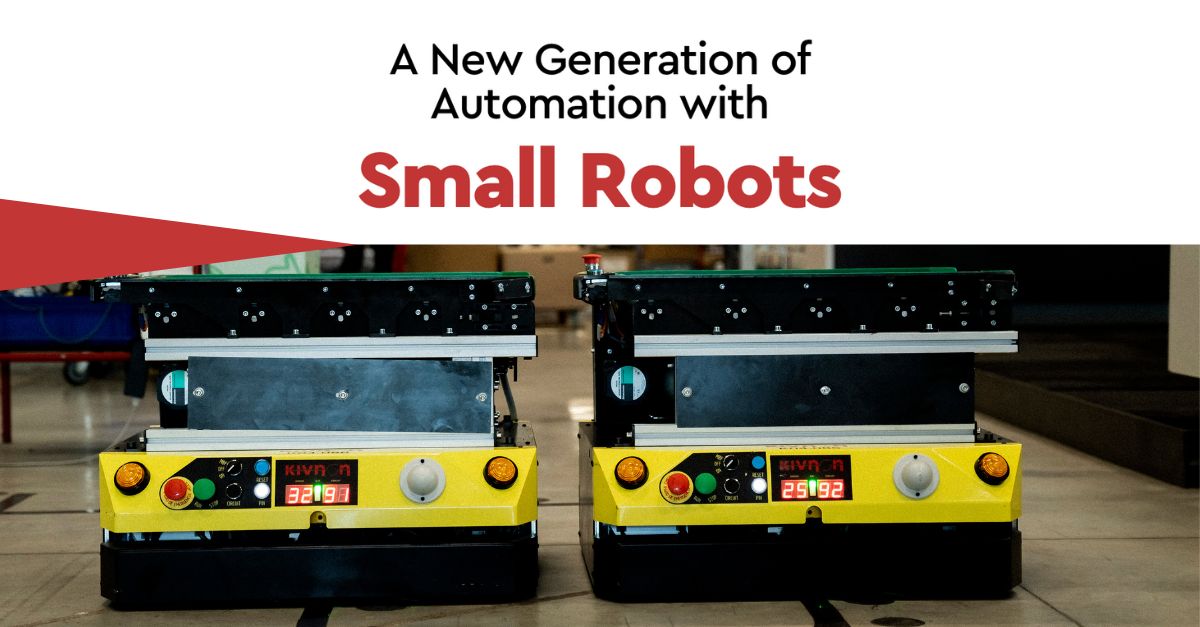

- Manufacturing Industry

Our partnership with manufacturers across diverse domains has enabled us to optimize internal logistics and material flows, including assembly lines. From raw materials to finished products, the adaptable nature of our robotic solutions simply revolutionizes the manufacturing landscape.

- Food & Beverage Industry

In an industry where time-sensitive deliveries and efficient warehousing are paramount, our adaptability facilitates precise material handling and swift order fulfillment. This agility translates to fresher products, reduced waste, and greater customer satisfaction.

- Pharmaceutical Industry

The pharmaceutical industry demands accuracy and compliance. Our adaptable robotic systems assist with safely transporting highly valuable medical supplies and products, ensuring regulatory standards are met and product integrity is maintained.

- Retail Industry

Quick inventory turnover and accurate order fulfillment are really important in the retail industry. Our flexible robotic solutions facilitate streamlined stock management and order picking, contributing to a more efficient supply chain and improved shopping experience for customers.

Mobile robots have become truly indispensable assets in modern intralogistics – automating tasks, optimizing processes, and enhancing safety. Since 2009, we’ve proudly offered innovative robotic solutions to industries around the world.

Want to revolutionize your internal processes with agile, automation-driven robotic solutions? Contact us here.