Kivnon’s approach to minimize risks

When integrating human-robot collaboration in manufacturing, it is crucial to understand

and address potential risks and challenges. Safety hazards are a primary concern, as the close interaction between humans and machines poses unique

challenges.

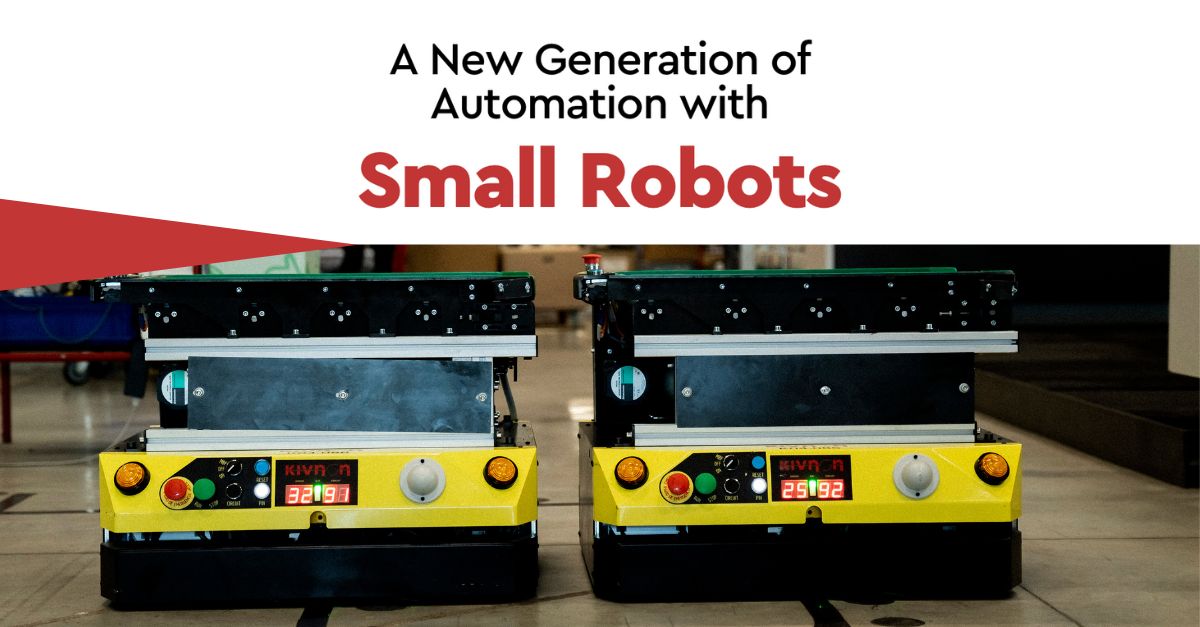

1. Sensor Technology

Kivnon mobile robots are equipped with sensors, offering complete 360-degree environmental awareness. This feature enables them to identify obstacles, including personnel, and implement measures to avoid any accidents.

2. Emergency stop systems

Each AGV/AMR is integrated with an emergency stop function that workers can engage. This system ensures the immediate cessation of the vehicle's movement when necessary.

3. Clear signaling

Designed for maximum visibility, the robots are equipped with distinct signals, such as flashing lights and LED displays, to announce their presence and intended direction, thereby aiding in the prevention of any accidental encounters.

4. Safety checks and maintenance

To guarantee optimal safety, AGVs/AMRs undergo regular maintenance and safety inspections. This process includes evaluating the efficiency of sensors, the effectiveness of brakes, and the overall mechanical soundness.

5. Specialized training

Kivnon ensures that operators of our mobile robots receive thorough training focused on safe vehicle operation. This training covers the understanding of safety features, operational guidelines, and handling procedures.

We place a high emphasis on safety in our robotic solutions, ensuring the well-being of human collaborators in manufacturing environments.

Simultaneously, the implementation of our technologies significantly boosts productivity.

These innovations streamline processes, reduce manual labor, and increase efficiency, all while ensuring a harmonious and secure interaction between humans and machines.