Faurecia Vitoria's plant meets the demands of a new client—

—while improving operational harmony, transitioning from chaos to order.

OBJECTIVES

Faurecia's needs were clear: expand their buffer of AGVs at the end of the production line to accommodate their needs.

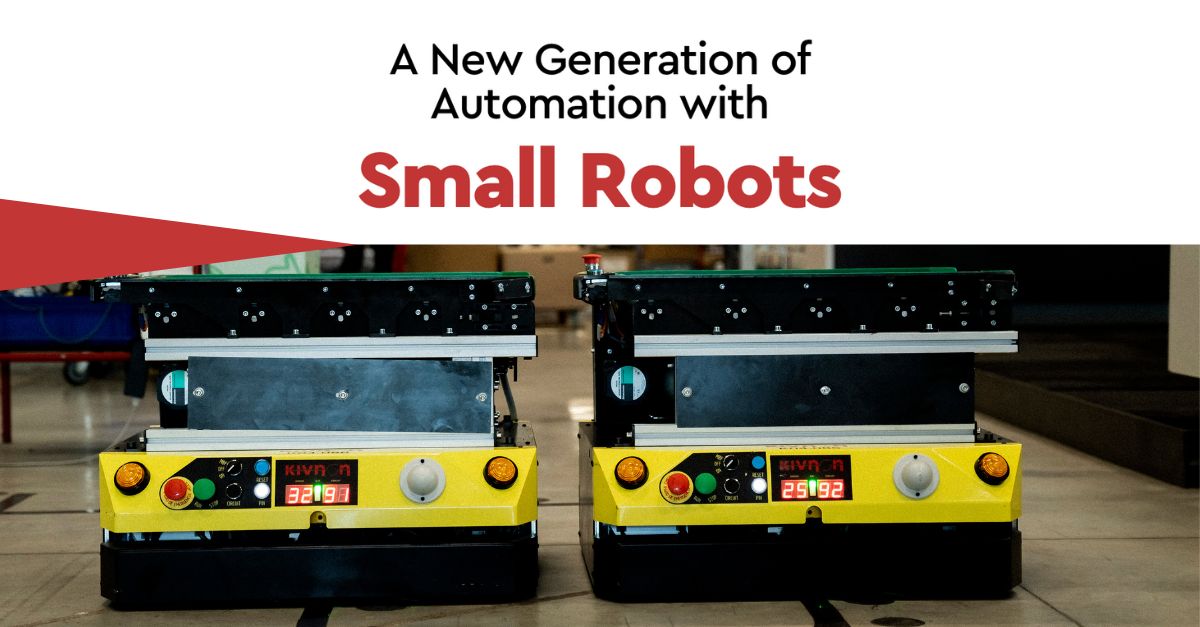

The solution Kivnon offered was to implement some of our K05 production systems with Siemens RFIDs to integrate them into Faurecia's existing infrastructure.

Transforming their chaotic storage landscape into an organized hub.

PAIN POINTS

Storage Chaos: Faurecia faced the challenge of disorganized storage, in accommodating the production demands of a new client. The existing storage was chaotic and inefficient.

Handling Inefficiencies: Navigating through warehouses and handling finished seats resulted in time-consuming processes and increased the risk of errors.

Limited Visibility: Faurecia lacked real-time visibility into stock levels and shipping statuses, making it difficult to make informed decisions.

KIVNON SOLUTIONS

Automation Solutions: Kivnon provided productive systems with RFID technology. These mobile robots integrated into Faurecia’s existing infrastructure, transforming the storage landscape from chaotic to organized.

Efficiency Gains: With this new implementation, Faurecia bid farewell to manual handling inefficiencies, retrieving finished seats and organizing them within the buffer, optimizing logistics and streamlining operations.

Real-time Monitoring: The integration of RFID tags enabled real-time monitoring of stock levels and shipping statuses. This way they gained unparalleled visibility into their inventory management processes, empowering them to make informed decisions.

Optimización del espacio: Faurecia recuperó un valioso espacio útil, maximizando la utilización de sus instalaciones.

In conclusion, the success of Faurecia's transformation underscores the transformative potential of embracing automation and intelligent systems.

Through strategic collaboration with Kivnon, Faurecia positioned itself for sustained growth and organization in the dynamic automotive landscape, proving that efficiency and collaboration are the driving forces behind success in the modern era of manufacturing.