What is an AGV?

The AGV is a mobile robot that follows predetermined instructions or signals to move around and complete actions (such as picking up or dropping materials) autonomously.

Differences between AGV and AMR

Many people would say that there is no difference between them, but in fact, there is one. Meanwhile, AGVs start/stop when they sense a human presence, while AMRs have obstacle avoidance capabilities; they do not stop, but try to find another way to get to where they need to go.

4 Types of Automated Guided Vehicles (AGVs)

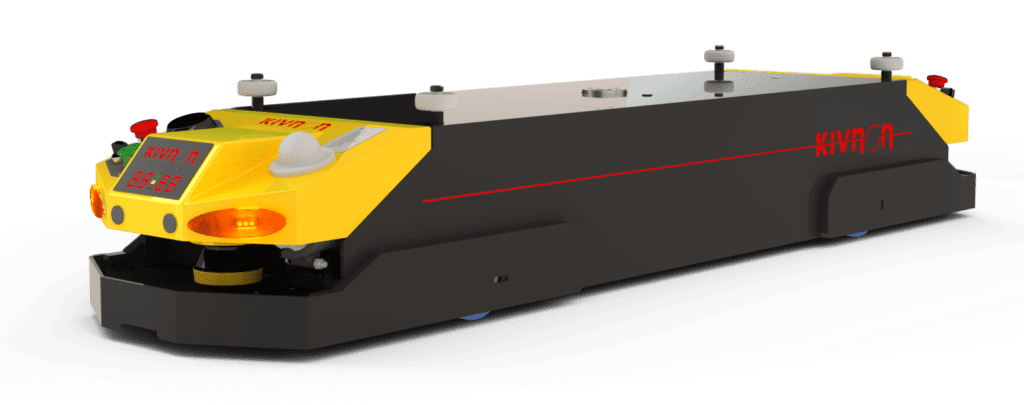

This type of mobile robot drives underneath payloads. They are connected to it with tow pins or lift modules. They are most commonly used for moving semi-finished goods between different production stations. Widely used in automotive or e-commerce applications.

Although these mobile robots are purchased in large quantities, they are the most affordable ones. Another benefit of this kind of AGV is that they are the most flexible and adaptable ones because of their dimensions.

You may also know it as an AGS (Automated Guided Vehicle) or Mouse AGV.

Simply refers to any AGV with forks. They perform similar tasks to automated forklifts but are designed from the ground up for automated operation only.

Although forked AGVs cost significantly more than manual forklifts, their efficiency benefits often lead to a significant return on investment of 1 or 2 years. Forked AGVs also have very low maintenance costs and are easier to repair.

Finally, although it may seem otherwise, this mobile robot is safer than forklifts. Forklifts cause more than 10% of accidents in factories, while automatic vehicles are equipped with safety features that make accidents under normal working conditions virtually impossible.

This type of AGV hitches to payloads such as carts and other logistics trains. These mobile robots offer towing capacities ranging from 500 kg to even several tons. They can also move several carts, offering high throughput. Despite their heaviness, they are so versatile that they can be implemented in many sectors, indoors and outdoors in all weather conditions.

An example of this Tow Tractors AGV is the transfer of parts to an assembly line.

Unit loads AGVs carry their payloads on top. They can be used in different transfer devices such as conveyors and lift platforms.

This mobile robot is capable of carrying a diverse range of loads. They can be used to transport everything from light goods to robotic arms or multi-tone steel coils.

They are also known as Turtle AGVs.

After all, you have discovered just a few key points of the incredible and ever-expanding world of AGVs and mobile robots. If you have any questions or are interested in learning more, please feel free to contact us. We will be happy to help you!